Simulation of Activated Carbon Reactors

What are the benefit of hydrograv simulations?

- proof of the flow conditions and improved mixing and hydraulic residence time

- efficient dimensioning of agitators

- prevention of depositions

- maximization of separation in the settling tank

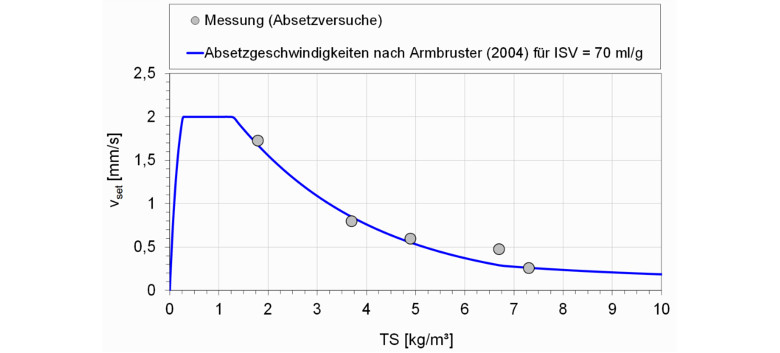

Example 1: Measurement of settling velocities

- investigation of sludge properties

- settling tests

- calibration of the settling models

Figure: Comparison between measured and simulated settling velocities.

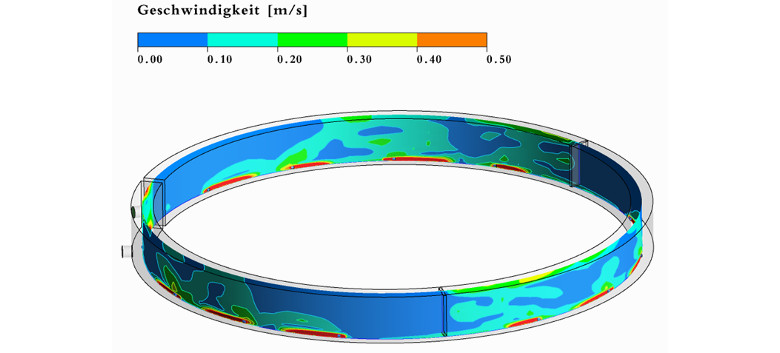

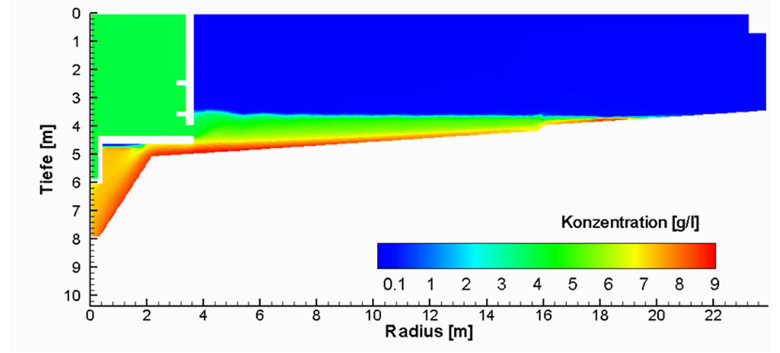

Example 2: Simulation of a contact reactor with inner settling tank

- optimization of mixing in the reactor

- maximization of particle separation in the settling tank

Figure: Flow velocities in the contact reactor designed as a ring-shaped tank.

Figure: Concentration of a mix of activated carbon and activated sludge in a settling tank. Illustration on a vertical plane.

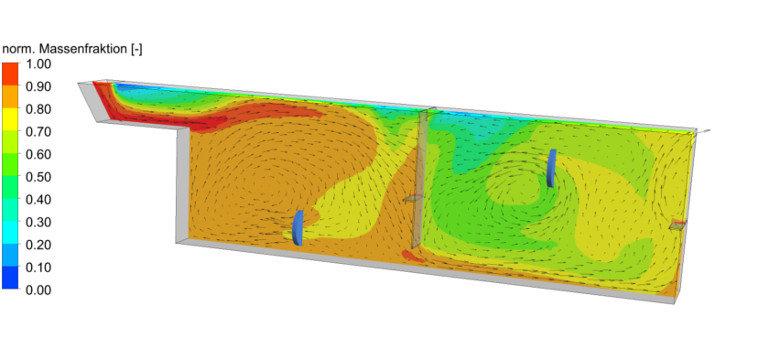

Example 3: Optimization of a contact reactor

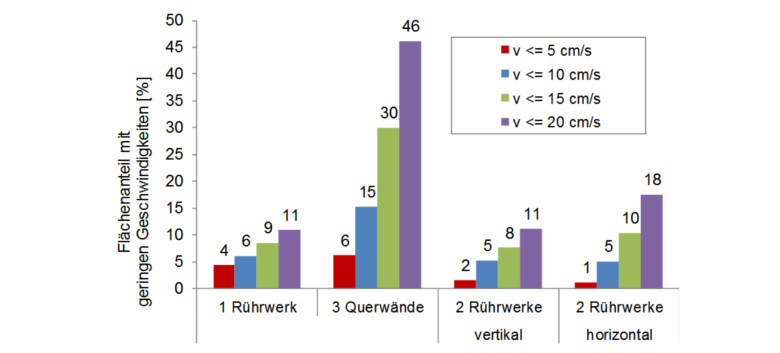

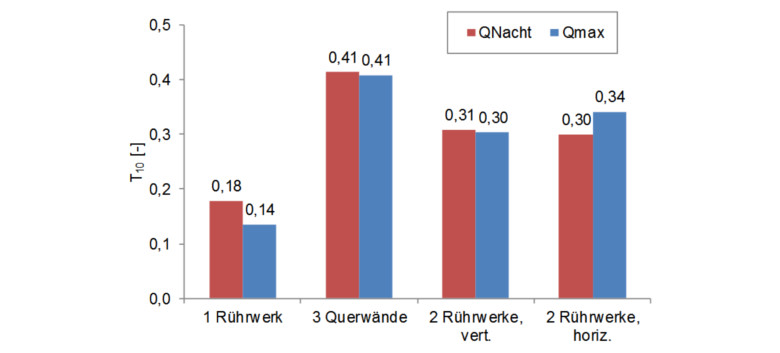

- optimization of the number of agitators, the agitator’s thrust and their orientation

- installation of deflection baffles

- minimization of depositions

- minimization of the energy consumption for mixing

- proof of different loading cases: the preferred variant is the best compromise between dry weather and stormwater flow

Figure: Distribution of particles as normalized mass fraction.

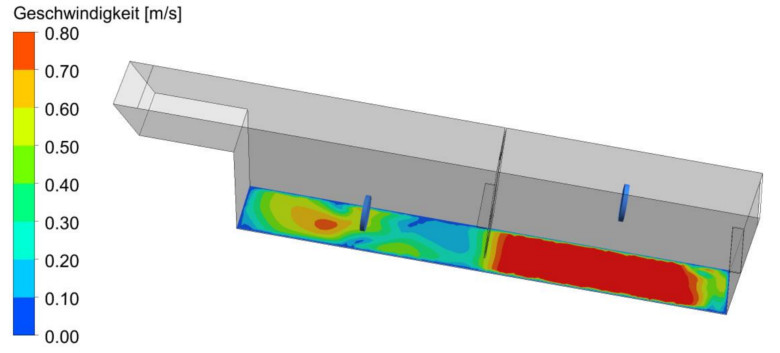

Figure: Velocities close to the bottom as proof for depositions.

Figure: Deterministic analyses of the velocities close to the bottom as proof for depositions.

Figure: Statistical analyses of a tracer simulation, here showing the 10 %-percentile as proof for short-circuit flows.