Simulation of Pumps and Pump Basins

What are the benefits of hydrograv simulations?

With hydrograv simulations, disadvantageous pump flows or pressure fluctuations in the pump basin, for example, can be detected and rectified at an early stage. This avoids overloading and early failure. Simulations can be applied for:

- Optimization of inflow

- Increased life time

- Evaluation during planning

- R&D-support, e.g. for pump manufactures

- Verifying hydraulic losses

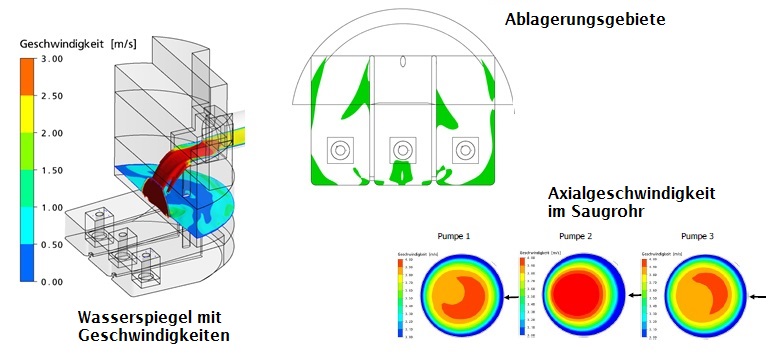

Investigation of a sewage pumping station

During the planning phase, the geometry of a pump basin is examined. The first planning variant showed hydraulic deficits. The revealed weak points led to further development of the geometry. The final optimizied geometry minimizes depositions and leads to a uniform flow to the pumps.

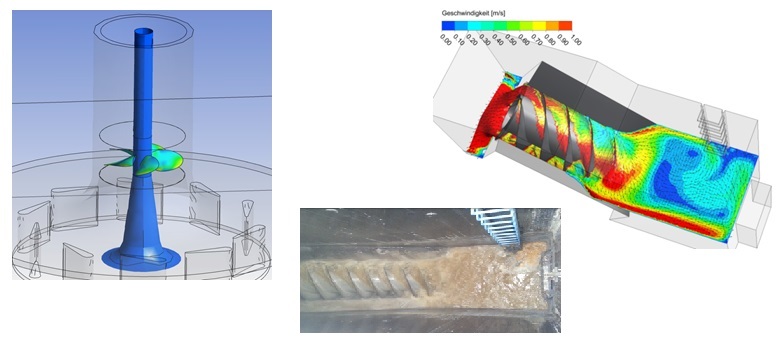

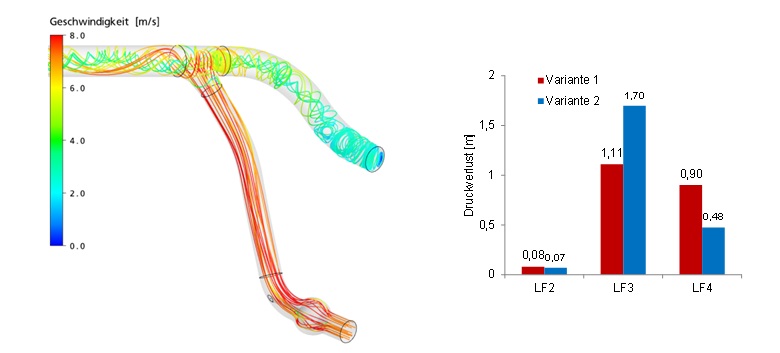

Investigation of a pumped-storage power plant

hydrograv simulations can be used to investigate pumped-storage power plants with different operating states (pumping to the upper reservoir or releasing towards a turbine ). In the following example, different loading cases are verified and different loads on a Y-pipe are determined:

- angular and linear momentum

- hydraulic losses

- forces on the Y-pipe

The result of the simulation study is thus the development of a template for the planner for the design and mechanical fastening of the system.

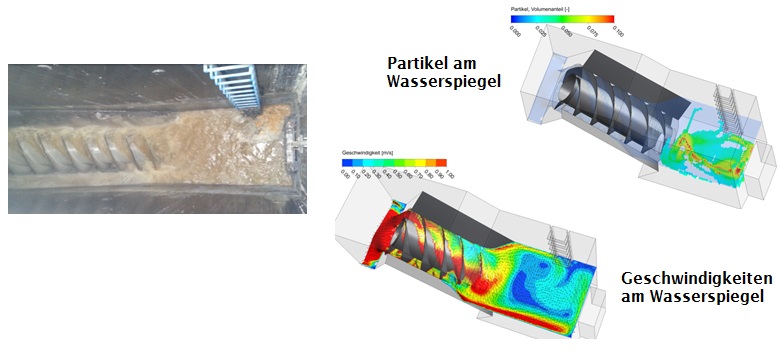

Investigation of an Archimedes screw pumping station

During operation a layer of floating sludge occurs in the pump basin which has a disadvantageous effect on the operation of the following waste water treatment plant.

hydrograv simulations are used to identify disadvantageous flow patterns. A reduced volume of the pump basin is developed which minimizes these effects.