Retention Basins

What are the benefits of hydrograv simulationen?

A retention basin is used to manage stormwater runoff. The critical points in the planning and operation of retention basins are often not only the flow through a basin itself but more frequently the hydraulic distribution in the inlet, e.g. in the form of a flow dividing structure or in the handling of large quantities of water. Thus, often special structures are part of the investigations.

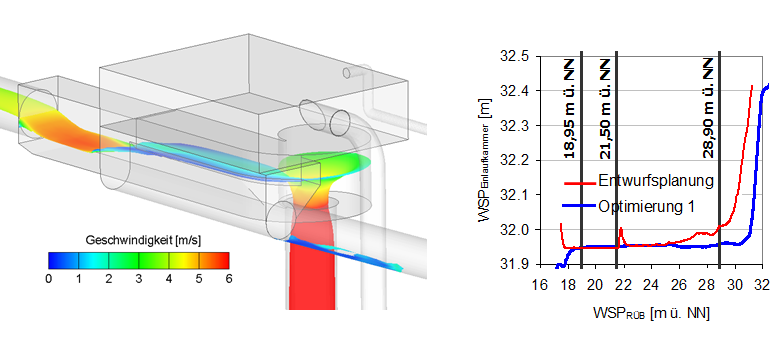

Vortex manhole in the inlet of a retention basin

A vortex manhole was planned according to the German design guideline DWA-A 112. Because of the large flow rate of 10 m³/s and expected backwater effects during the filling process of the basin uncertainties in the determination of hydraulic losses appeared. Therefore the planning variant was verified with hydrograv simualtions and optimized to increase the efficiency.

Backwater effects are investigated during the filling process of a retention basin upstream of a vortex manhole. For example, the results of the simulation show that due to the unexpectedly high hydraulic losses a sumberged overflow instead of a free overflow developed. This had an impact on the connected sewer as the projected discharge of 10 m³/s could only be discharged for a shorter time. Therefore a modified design of the inlet chamber of the vortex manhole including an emergency overflow was developed.

Backwater effects are investigated during the filling process of a retention basin upstream of a vortex manhole. For example, the results of the simulation show that due to the unexpectedly high hydraulic losses a sumberged overflow instead of a free overflow developed. This had an impact on the connected sewer as the projected discharge of 10 m³/s could only be discharged for a shorter time. Therefore a modified design of the inlet chamber of the vortex manhole including an emergency overflow was developed.

Nonuniform flow through a retention basin

A very large nonuniform sedimentation of sand occurs in a retention basin which leads to an increased cleaning effort for the operator.

These sedimenations can be verified with hyrdrograv simulationen and optimization measures suggested.

At the same time a nonuniform hydraulic and material distribution between the three chambers of the basin is determined.

Verification of a retention basin with a flow dividing structure

The filling of a retention basin is proven with hydrograv simulations. Due to its large size (max. inflow rate 38 m³/s) this structure cannot be reliably planned with standard analytical methods. With simulations various optimization measures are developed to ensure the functionality of the system, e.g. the minimization of hydraulic losses, the avoidance of depositions or the best possible arrangement of a fine bar screen in the flow dividing structure.