ADAPT Next – The smart solution.

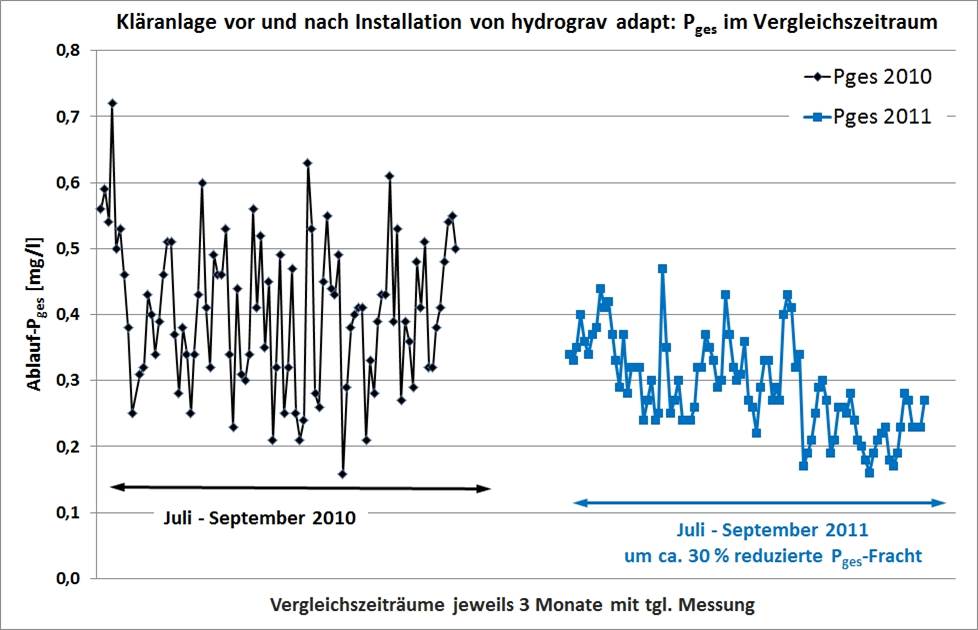

0.2 mg/l Pges in the effluent of wastewater treatment plants now also without filter

Secondary clarifiers are the “problem children” of many wastewater treatment plants, the cause of high effluent turbidity and the “bottleneck” of the hydraulic load capacity of the entire wastewater treatment plant.

The hydrograv GmbH could show that the cause of all these problems is the rigid design of the inlet structures. It appears that a rigid structure is almost always in the wrong place with the wrong geometry: in dry weather too high to minimize the turbidity, in rainy weather too low to not whirl up the settled sludge. Therefore it was clear: the inlet structure must be designed variably, the concept for hydrograv adapt was born.

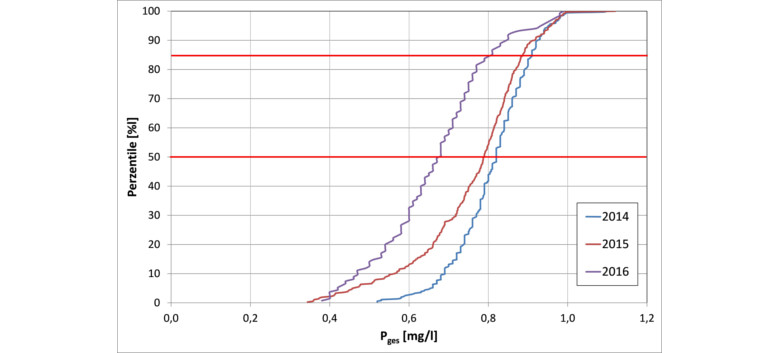

Since 2018 the adapt system has been proving that very good things can also be improved: since then the patent-pending phosphorus elimination ring – PER – ensures that even clearer water flows out of the tanks. Already in use at several plants, for example in Frankenberg/Eder and in Schlüchtern, it has already proven over many months that the total phosphorus in the effluent of a wastewater treatment plant can be reduced to monthly average values of only 0.2 mg/l Pges with the adapt Next system with PER, even without additional filtration.

hydrograv adapt Next with PER solves the TSS problem at its cause – the inlet of the secondary clarification – instead of curing the symptoms with one filtration only, which is expensive and energy and maintenance intensive.

hydrograv adapt at a glance:

The main advantages of the height-variable inlet system

- No more sludge overflow by securing the flock filter effect.

- Less sludge displacement in rainy weather makes for a higher sludge concentration and thus for better degradation capacity in the activation.

- A lower sludge level and a stable sludge bed lead to increased operational safety.

- Minimal particulate phosphor and COD in the effluent. On average and in the tips. I.e. sustainable water protection and conservation of wastewater levy.

- Flock filter in the secondary clarification instead of the downstream filtration. This minimized investment costs and significant energy savings.

- Ideal support for elimination removal with activated carbon.

- More mixed water through the wastewater treatment plant.

- Expanding without building new secondary settling tanks.

Thus hydrograv adapt defines the state of the art in the equipment of secondary settling tanks.

hydrograv adapt – a patented technology of the hydrograv GmbH.

Learn more details about ADAPT Next

Flow simulations of hydrograv to over one hundred secondary settling tanks show that this concept is almost always cheaper for continuous low effluent values, a high load capacity and the avoidance of sludge overflow.

Abbildung:

Look into two secondary settling tanks of a wastewater treatment plant with an old fixed inlet structure (left) and with the hydrograv adapt inlet structure (right). Significantly fewer flocks in plain water!

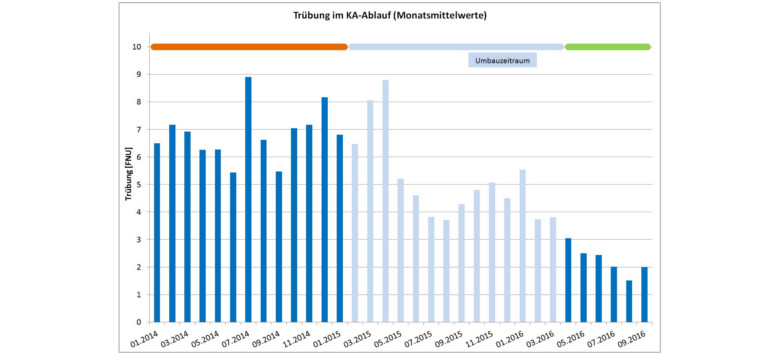

In the meantime this rugged construction ensures impressive results for several years on a variety of wastewater treatment plants:

- Discharge values that can usually only be reached with the installation of sand filter systems – at a fraction of the cost, the energy input and the maintenance requirements.

- Further phosphor elimination goals can be achieved with hydrograv adapt at a fraction of the previously anticipated financial expenses.

- Hydraulic loads become reliably treatable, which was considered impossible previously.

Some of many examples of these excellent operating results can be found on the following pages. We gladly send you further references. You are welcome to arrange viewing appointments on wastewater treatment plants in your area with already refitted secondary settling tanks with us as well.

With hydrograv adapt the hydrograv GmbH consequently makes a significant contribution to the environmental protection – while protecting the financial resources of the wastewater treatment plant operators.

State of the art and more

THE HYDROGRAV ADAPT INLET SYSTEM

Tried and tested in practice for years

Until today several dozens of hydrograv adapt systems have been installed and prove their reliability cumulatively over several hundred years of operation. The success for our environment in the installations: regularly much clearer wastewater in the outlet than with the previously existing rigid inlet constructions. This also applies to various “rigid optimizations” built by third parties according to CFD analyses, which in the meantime have been replaced by hydrograv adapt with “clear” success.

Successful for the environment

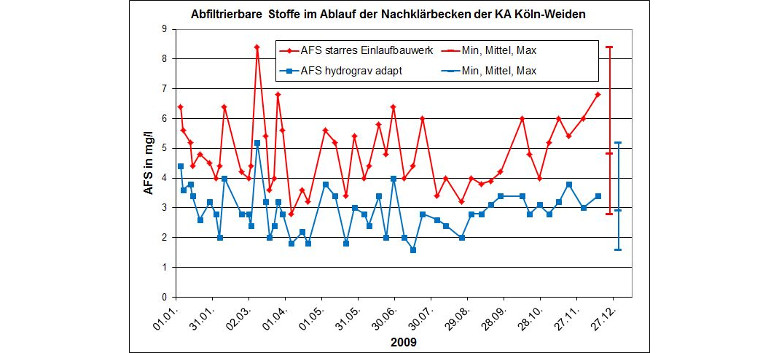

To redefine the state of the art, a technology must reduce the emissions of a plant into the environment to a new, clearly lower level. Exactly this is the result of dozens of installations of hydrograv adapt inlet systems: the average filterable substances measured by the operators are at 2 to 3 mg/l regularly and thus the particulate phosphorus in the effluent of the secondary clarification is at the lowest level. Again and again the total phosphorus effluent values of the wastewater treatment plants equipped with adapt decrease by almost the entire amount of particulate phosphorus – completely without downstream filtration. The state of the art for filterable substances in the effluent of wastewater treatment plants is thus defined by the emission values achievable with adapt systems, which are on average well below 5 mg/l.

Known by experts

The state of the art is establishing itself as a generally accepted rule of the art due to its familiarity among technical experts and its sustained success in practical operation. Both is constituted by hydrograv adapt. Since the success of the prototype in Cologne Weiden more than 10 years ago numerous articles have been published, various lectures at seminars and further education events have been held. Also the wastewater treatment plant operators themselves inform in lectures again and again about the success of the technology, for example at wastewater treatment plant neighbourhood meetings.

Since 2016, the height-variable solution for the inlet geometry of secondary clarifiers has been mentioned in the German standard work of dimensioning, the worksheet DWA-A 131.

hydrograv adapt – Generally accepted rules of technology

All this allows only one conclusion: hydrograv adapt is more than just state-of-the-art technology. The equipment of secondary clarifiers with hydrograv adapt meanwhile fulfils the characteristics of the generally accepted rules of technology!

hydrograv adapt has been enjoying a steadily increasing popularity both nationally and internationally since its first commissioning in 2007. And not only that, the number of adapt installations abroad is also increasing. Always with the same results: clearer water in the effluent with simultaneously increasing efficiency and safety of the secondary clarifiers.

For further information please click here or contact us directly.

“Generally accepted rules of technology” are those techniques which are considered by expert second and third parties from the respective industry as a solution for legally defined goals and which have already proven themselves in practice over several years or will prove themselves in the near future.1

1 https://de.wikipedia.org/wiki/Anerkannte_Regeln_der_Technik

Our successes

HYDROGRAV ADAPT-INLET SYSTEMS

Cologne-Weiden

hydrograv adapt ensures a working flocculation filtration already in the secondary clarification at any load. And with manageable technical effort, with slight energy requirement and low-maintenance. In addition, so the capacity of the secondary settling tanks is increased.

Sludge overflow and flock output – for all the progress of the wastewater technology, this is still a major problem in many wastewater treatment plants. Yet this leads to

- unnecessary environmental pollution,

- high wastewater charges and

- exceedance of the discharge limits.

It is known that secondary settling tanks have very good discharge values when the sludge is introduced into the tank below the sludge level. Then the flock filter works – and that is as effective as the expensive and energy-intensive downstream technical filters. hydrograv adapt exploits this flock filter always consistently with its height-variability.

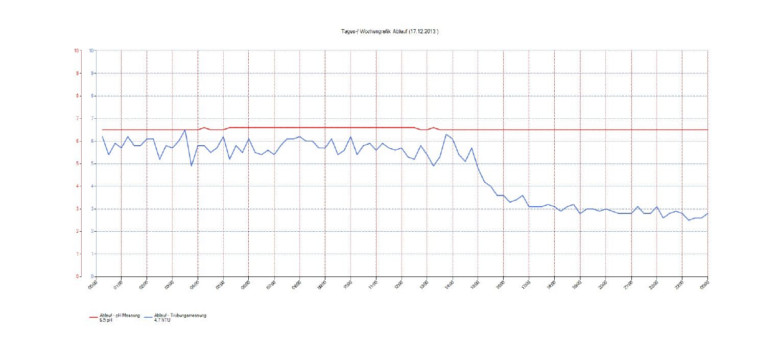

IIn September 2007, the first hydrograv adapt inlet structure was put into operation in a secondary settling tank at the wastewater treatment plant Cologne-Weiden. The second secondary settling tank of this wastewater treatment plant is equipped with a conventional fixed inlet structure. A comparison of the operating results of both tanks is advisable.

A tank equipped with hydrograv adapt consistently shows better results:

- significantly lower sludge level, especially in rainy weather; i.e. higher security against sludge overflow or a higher hydraulic capacity as well,

- smaller filterable substances and considerably less visible fine flocks in the discharge,

- greater visibility depth (i.e. clear water),

- significantly lower floating sludge formation.

Picture: Comparison of sludge level positions in the two secondary settling tanks of the WWTP Cologne-Weiden, on the left a dry weather period, on the right a rain period. Difference of the sludge blanket layers are up to 80 cm.

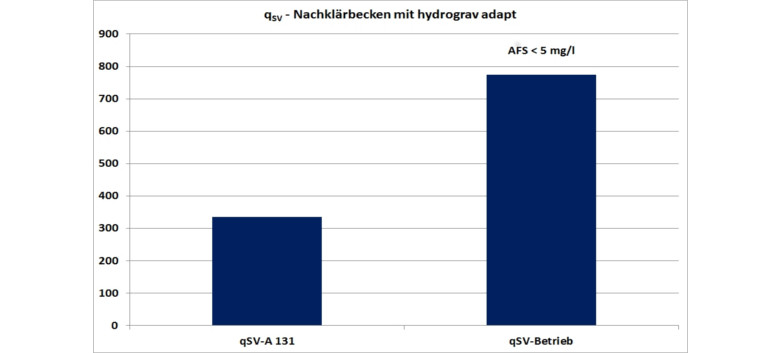

Picture: qSV charges of 230 % of the permitted limit according to DWA-A 131 could be treated reliably in the hydrograv adapt tank. qA = 2 m/h.

Higher reliable secondary settling tanks enable lower combined sewer overflows in the catchment area, and even that is active water protection, because:

- Connecting new catchment areas without the need to build a new secondary settling tank.

- Relieve less wastewater uncleaned – more mixed water through the wastewater plant.

- Forgo a bypass around the activation – or activate it only at much higher loads.

- Using released secondary settling tanks for other process steps such as the trace substance elimination.

- Picture: Comparison of filterable substance values in the discharge of the two secondary settling tanks of the wastewater treatment plant Cologne-Weiden. Continuously lower filterable substance values of hydrograv adapt tanks on average and in the tips.

Credentials

Here is a selection of references of hydrograv adapt systems.

The success of an adapt-installation can be seen immediately in the secondary clarifier:

clear water in the outlet and a sinking sludge level. Therefore many of our satisfied customers have already equipped several of their treatment plants with adapt after the installation.

Altomünster

14.000 EW Bad Berleburg-Aue

5.800 EW Bad Berleburg Stadt

18.000 EW Bad Harzburg

40.000 EW Bad Marienberg

11.500 EW Chemnitz

400.000 EW Dorsten-Wulfen

30.000 EW Dresden Kaditz

740.000 EW Dülken

72.000 EW Erlangen

270.000 EW Frankenberg/Eder

29.000 EW Fürth

310.000 EW Großostheim

35.000 EW Haimhausen

8.800 EW Halle-Nord

300.000 EW Hünfeld

35.000 EW Jeddah Airport (Saudi Arabien) Kevelaer-Weeze

35.000 EW Köln-Rodenkirchen

88.000 EW Köln Stammheim

1,5Mio EW Köln Porz-Wahn

92.000 EW Köln-Weiden

80.000 EW Leuzbach

23.000 EW Marburg

155.000 EW Markt Indersdorf

20.000 EW Meckesheim

44.000 EW Moers-Gerdt

200.000 EW Northeim

75.000 EW Odelzhausen

8.000 EW Rednitzhembach

7.900 EW Regensburg

400.000 EW Sandhausen

125.000 EW Schlüchtern

27.500 EW Schwäbisch Hall

100.000 EW Stadtlohn

30.500 EW Weißenfels

76.500 EW Wolfsburg

170.000 EW Wuppertal-Kohlfurth

156.000 EW

ADAPT Next in the video

Downloads

Adapt Next at a glance:

Adapt 2.0 in the video:

Adapt 2.0 – technisches Datenblatt: